Brugg Pipesystems

Brugg FSR Safety Pipe was developed and launched to market in 1966, Brugg Pipesystems is a German manufacturer of extremely high quality flexible single and double wall stainless steel pipework. Safety Pipe is designed to contain flammable, hazardous and ground polluting fluids whilst being continuously monitored during operation.

The BRUGG flexible stainless steel pipe systems are an excellent alternative to rigid pipe; their innovative design offers extreme versatility for installation in a wide variety of setting both inside and outside buildings and above ground in a concrete trench or buried underground.

Compared to rigid plastic or steel pipe, BRUGG can be manufactured in continuous lengths of over 1,000 metres (depending on size and type of construction). This means that installation times are extremely quick and cost savings are made during installation.

Due to its flexible nature, the pipe can be pulled through suitably sized ducts, allowing other work to continue.

FSR and Secon-X types of pipe can be permanently monitored for leakage with a pressure or vacuum leak detector.

Why Engineers choose BRUGG

- Safe and reliable pipe, manufactured and tested to extremely high standards; EN14125, EN729-2, CE marked and compliant with 97/23/EC European pressure directive for pressure equipment

- 316L Stainless Steel core pipe construction is certifiably suitable for varied and extensive fields of application

- Electrically continuous, UV Stable and self-compensating for both pressure and temperature changes

- Spiral corrugated ‘endless’ construction gives excellent flow characteristics and a self-cleaning flow pattern, with pressure losses that are similar to equivalent NB smooth bore steel pipework.

- Flexwell pipes have a minimum design life of 30 years.

- Quicker installation than rigid plastic or steel

- multiple bends possible in one continuous length – no joints needed

- Excellent temperature ratings; +60◦C down to -30◦C with high corrosion resistance

- Pipe is fire resistant due to its high melting point and complies with the latest J5 building and PPG2 oil storage regulations

- Pipe can be delivered on a continuous length on a drum or coil

Some of the pipework we supply is listed below. For more information please contact our sales team.

Description: A flexible, double walled, Stainless Steel Pipe in Pipe, type approved, safety pipe system with permanent leak monitoring and R90 or R120 fire rating.

Construction: 316 Stainless steel core pipe, with 304 Stainless steel outer pipe designed for full working pressure and high-grade external corrosion protection jacket.

Working Pressure: PN 25. Special Construction: PN40/ PN50

Dimensions available: DN15 – DN150 (nominal bore NB ½” – 6″)

Areas of Application: Transport of environmentally hazardous, flammable, toxic, dangerous fuels, liquids and gases for Safety and Environmental Protection.

Special Features: Double walled Pipe in Pipe construction with surveillance space for continuous leak monitoring whilst in operation. Simple and fast laying in continuous lengths, short installation times, no welded connections, no pressure tests needed, no elbow fittings needed. A tried and tested system of protection for more than 40 years. National Approvals (type approved) and also International Approvals.

Fire Tested to R90 and R120 for passage through a fire rated compartment bulkhead.

Meets the requirements of European Regulations EN 13160 for protective systems of Class I.

For more detailed information download the Flexwell FSR datasheet.

Description: A flexible, secondary contained Pipe in Pipe system with permanent leak monitoring capability.

Construction: 316 stainless steel core pipe with spaced polyethylene (PE) outer jacket to give a pipe in pipe construction, the outer pipe is designed for monitoring purposes.

Working Pressure: Operating pressure up to 10 bar.

Dimensions Available: DN25 – DN100 (nominal bore NB 1” – 4″).

Areas of Applications: Suction pipes, pressure pipes, fill pipes and tank dump pipes. Transportation of water-pollutant, flammable, toxic and other dangerous liquids and gases.

Special Features: Fast and easy installation without welding, using mechanical connectors. Laying/ installation of a stainless steel pipe system in very long sections make installation times extremely quick.

Meets the requirements of European Regulations EN 13160 for protective systems of Class I.

For more detailed information download the Secon-X datasheet.

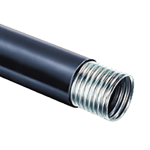

Description: A flexible single wall stainless steel pipe, can be supplied both with or without an outer polyethylene (PE) protective jacket.

Construction: Spiral corrugated 316 stainless steel core pipe for flexibility, supplied with or without a high quality polyethylene (PE) protective jacket.

Working Pressure: PN 6 to PN10.

Dimensions Available: DN 15 – DN 150 (nominal bore NB ½” – 6″).

Areas of Applications: Transport of gases, water, chemicals or as an inner liner for an existing pipe system or as a protective pipe/ conduit for other services (comms cables, fibre optic cables, power cables, air hoses etc).

Special Features: No welding work required on site, only easily installed mechanical connectors. Laying/ installation of a continuous stainless steel pipe system in very long sections make installation times extremely quick.

For more detailed information download the Niroflex datasheet.

Description: A single wall armoured stainless steel spiral corrugated liquid gas pipe with an outer polyethylene (PE) protective jacket.

Construction: Spiral corrugated 316 stainless steel core pipe for flexibility, with stainless steel pressure armouring bands and a high-quality polyethylene (PE) protective jacket.

Working Pressure: PN 25

Dimensions Available: DN 20 – DN 50 (nominal bore NB ¾” – 2”).

Areas of Applications: Underground or above ground transportation of any Liquefied Petroleum Gas (LPG) or high-pressure fluid, typically liquid feed line and vapour return between LPG storage tanks and liquid gas dispensers.

Special Features: Very simple and fast installation without the need for welding or radiographic testing. Only simple mechanical connectors at the very ends. Therefore no closure of site/ downtime on refits and minimal loss of site sales.

For more detailed information download the LPG datasheet.

Construction: Flexible, endless, spirally corrugated pipe system. Medium pipe: 316 Stainless steel.

System limits: PN 16.

Available in dimensions: DN 10 – DN 150.

Areas of application: Profiled (spirally corrugated) endless, flexible corrugated pipe for efficient heat transfer in heat exchanger construction, warm water storage, and in the exploitation of regenerative energy sources such as the generation of biogas and solar energy.

Special features: Optimum heat transfer, large surface area, high degree of thermal efficiency, easily formable, small bending radii, very economical due to the use of corrosion-resistant materials.

For more detailed information download the Spiraflex datasheet.

Construction: Rigid, double walled, approved safety piping system with permanent leak monitoring (Pipe in Pipe).

Medium pipe: Steel, stainless steel.

System limits: Operating pressure as appropriate for the plant concerned.

Dimensions available: DN 15 – 800 (with approvals).

Areas of application: Transport of environmentally hazardous, flammable, toxic, dangerous liquids and gases. Complements FLEXWELL safety piping.

Special features: Double-walled piping construction with surveillance space for die leak monitoring. Double-walled construction elements prefabricated and tested (acceptance test) at our works. With proof of static strength and compensation of longitudinal expansion due to temperature rise. Installation/project planning by specialist firms/plant construction. Safety piping system with national approvals in Germany.

Meets the requirements of future European regulations for

protective systems of Class I.

For more detailed information download the Stamant datasheet.

Description: A single wall stainless steel spiral corrugated heat exchanger tube. The heat exchange surface area of Bioflex tubing gives a 40% greater surface area than equivalent smooth bore stainless steel.

Construction: Spiral corrugated thin wall 316 stainless steel pipe for flexibility and to provide swirl in the flow to maximise heat exchange.

Working Pressure: PN 6

Dimensions Available: DN50 (nominal bore NB 2”) – other sizes available as required.

Areas of Applications: Heating coils in anaerobic digester applications or cooling coils in other applications.

Special Features: Continuous lengths of highly efficient 316 stainless steel heat exchanger tubing with no jointing, no welding and zero permeation. These features allow extremely quick installation time,s and a highly-efficient long-life system.

For more detailed information download the Bioflex datasheet.

Description: A single wall stainless steel spiral corrugated heat exchanger tube. The heat exchange surface area of Spiraflex tubing gives a 40% greater surface area than equivalent smooth bore stainless steel.

Construction: Spiral corrugated thin wall 316 stainless steel pipe for flexibility and to provide swirl in the flow to maximise heat exchange.

Working Pressure: PN 6 – PN 10

Dimensions Available: DN 15 – DN 40 (nominal bore NB ½” – 1 ½”)

Areas of Applications: Profiled (spirally corrugated) endless, flexible corrugated pipe for efficient heat transfer in heat exchanger construction, warm water storage, and in the exploitation of regenerative energy sources such as the generation of biogas and solar energy.

Special Features: Optimum heat transfer, large surface area, high degree of thermal efficiency, easily formable, small bending radii, very economical due to the use of corrosion-resistant materials.

For more detailed information download the Spiraflex datasheet.

Description: Rigid, double wall, approved safety piping system with permanent leak monitoring (Pipe in Pipe). The system is computer designed/ modelled to minimise operating loads and stresses then pre-constructed and tested off-site with minimised site welds.

Construction: Rigid double walled steel or stainless steel approved safety piping system, with permanent leak monitoring (Pipe in Pipe).

Working Pressure: Operating pressure as appropriate for the plant concerned up to PN 200.

Operating temperature: -50°C – 300°C (more on demand).

Dimensions Available: DN 15 – 800 (with approvals), (nominal bore NB ½” – 32”).

Areas of Applications: Transport of environmentally hazardous, flammable, toxic, dangerous liquids and gases. Complements FLEXWELL safety piping.

Special features: Double-walled piping construction with surveillance space for leak monitoring. Meets the requirements of European Regulations EN 13160 for protective systems of Class I.

For more detailed information download the Stamant datasheet.

Further information can be found via the BRUGG website.