EBSRAY Pumps Australia

Ebsray Pumps designs and manufactures a comprehensive program of Positive Displacement and Regenerative Turbine pumps for a wide range of industrial applications. Now part of the PSG Group Ebsray is acknowledged as one of the leaders in the world’s pump industry offering products of unparalleled quality, efficiency, innovation and reliability.

With a vast experience in the industrial pumping area coupled with the expertise acquired over 75 years has enabled Ebsray pumps to become a market leader in innovative design for ‘niche’ industrial markets. Commitment to application engineering, design, development, manufacture, and supply of specialist pumps has placed Ebsray pumps in the Industries’ front line for LPG/ Autogas Pumps and Industrial Transfer Pumps for oils, greases, bitumen and viscous fluids.

Ebsray’s recent successes in the LPG industry, military equipment refueling systems and bulk potable water transfer has confirmed the company’s ability to adapt it’s products and manufacturing capability to the world markets.

The product range we supply includes:

LPG Products

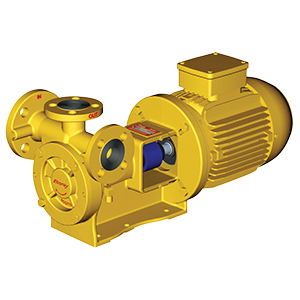

- Regenerative turbine pumps

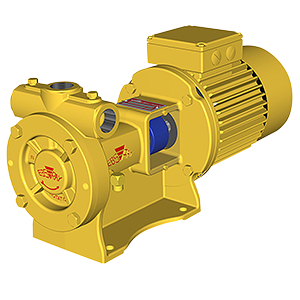

- Sliding vane pumps

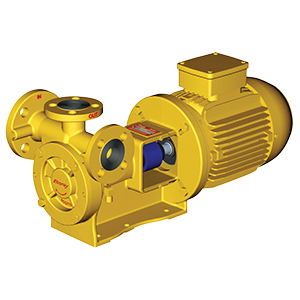

- Bypass vane pumps

- Bypass valves

- LPG ancillary Equipment

Industrial Pumps

- Internal Gear Pumps

- Sliding Vane Pumps

- Helical Gear Pumps

- Lobe Pumps

- Regenerative Pumps

- Centrifugal Pumps

Ancillary Equipment

- Bypass Valves

- PFM System

- Strainers

- Bitumen Spraying Equipment

Ebsray’s recent successes in the LPG industry, military equipment refuelling systems and bulk potable water transfer has confirmed the company’s ability to adapt its products and manufacturing capability to the world markets.

Why Engineers Choose Ebsray

- Over 80 years experience in manufacturing pumps

- Application led development to provide the best pumping solution

- Innovative designs backed up by high quality manufacture

- Efficient pump designs that are inherently reliable

Below are the products we manufacture:

Fields of Application:

Specially designed for low-flow, high-pressure duties on low-viscosity liquids such as LPG, propane, butane, DME, CO₂, refrigerants, anhydrous-ammonia, boiler feed etc.

Exceptional performance and reliability even under extremely low NPSH operating conditions combined with the ability to handle entrained vapours without undue loss of efficiency or internal damage. Underground, aboveground and submersible LPG pumping performance is exceptional.

Constructional Features: (Not applicable to all models)

- Direct coupling to synchronous-speed electric motors – 50Hz/60Hz

- Heavy-duty sealed-for-life bearings – can accept belt-drive loads

- Self-venting robust casing design

- Balanced mechanical seal – simple, reliable

- Throttle bush as standard – added safety feature

- Extremely quiet operation

Materials of Construction

- Casing – ductile iron, steel

- Impeller – bronze, ductile iron

- Shaft – high-tensile alloy steel

- Special materials to specification

For more detailed information download the LPG product brochure.

Constructional Features

- Low maintenance – single stage impeller

- Close coupled to standard IEC frame B5 flange mounted 2-pole motors-EExe or EExd protection

- Unique cartridge design mechanical seal Integral API 682-ISO 21049 compliant throttle bush

- Extremely quiet, vibration-free operation

- Very simple to service

Materials of Construction

- Casing – Ductile Iron to ASTM A395

- Impeller – Bronze as standard

- Shaft – High tensile alloy steel

- Special materials to specification.

Range of performance

- Flows to 90 L/min

- Pressures to 2400kPa

- Power Range 1.5, 2.2 & 3.0kW

- Speeds to 3500 RPM

Model Lineup

- RC20 – 29 L/min @ 700kPa (7 Bar) – 50Hz

- RC25 – 52 L/min @ 700kPa (7 Bar) – 50Hz

For more detailed information download the RC20/RC25 data sheet.

With a similar set of design principles to the RC20/ RC25 pumps the RC40 model enhances performance by increasing flow rates and versatility while reducing overall pumpset costs.

The RC40 is suitable for the transfer of a wide variety of liquefied gases, including LPG, Autogas, DME, Aerosols, CO2 , Industrial refrigerants and Anhydrous ammonia.

Applications

- Transfer and industrial dispensing

- Cylinder filling

- Driveway/vehicle filling, up to 4 hoses

- Forklift refueling

- Direct burner and vaporizer feed

- Above ground and underground tanks

RC40 Construction Features

- Single-stage impeller providing high performance with low maintenance requirements

- Close-coupled flange design mounts to both 50Hz and 60Hz (NEMA and IEC) electric motors

- Unique 3-ported design (two discharge ports) allows flexibility with lowered installation costs

- Next generation hydraulic design, RC40 optimizes it’s class-leading performance and efficiency by using the same sized motor for better performance than it’s leading competitors

- Cartridge design mechanical seals and bearings are interchangeable with RC20 and RC25

- Flanged (ANSI #300 & DIN PN40) and Screwed (NPT) ports all in one body design.

Features & Benefits

- One flange fits NEMA and IEC B5 and B14 Motors

- Close-coupled design can also be long-coupled

- Three-ported design (two discharge ports)

- Simple single-stage design

- Ductile iron pressure retaining parts (Body/cover)

- Shaft: High tensile alloy steel

- Unique cartridge design mechanical seal

- Complies with ATEX, UL51*, and AS1596 codes

- Versatile flange options: NPT, ANSI or DIN

Performance Data:

- Motor speeds up to 3,500 rpm

- Flow rates to 200 L/min

- Maximum differential pressure to 14 bar (200 psi)

- Hydrostatic test pressure 70 bar (1,016 psi)

For more detailed information download the RC40 data sheet.

Model RX10 & Model RX33 Submersible Regenerative Turbine Pumps The Ebsray Model RX33 Regenerative Turbine Pumps are specifically designed and precision-built for efficient high-pressure pumping of LPG, autogas, propane and butane from underground or aboveground storage tanks.

Applications

- Autogas driveway dispensing for up to 4-6 hoses, site and usage dependent

- Forklift refuelling

- Aerosol industries

- Agricultural industries

- Marine dispensing

- Cylinder filling

- Direct burner or vaporizer feed

Features & Benefits

- Single-stage regenerative turbine pumping element

- Quiet, smooth, pulse-free operation

- Submersible concept guarantees rapid priming and pressure generation

- Internal BCL™ “Bearing Cooling and Lubrication” system for ultimate pump reliability

- Ebsray “Three-tier” protection system for pump, motor and pumping system

- High differential-pressure capability

MODEL RX10: ATEX/ANZEx certified explosion-proof design submersible electric motor

MODEL RX33: IECEx/ATEX certified explosion-proof design submersible electric motor

RX10 Technical Data

Materials:

- Ductile iron to ASTM A395/steel casing

- Impeller – Bronze

Porting:

Inlet: DN 50 (2 in.) nominal

Discharge: DN 50 (2 in.) NPT(F)

RX10 Performance Data

- Max. flows: 103 L/min

- Max. differential pressure: 9 bar (130 psi)

RX33 Technical Data

Materials:

- Ductile iron to ASTM A395

Porting:

Inlet: DN 38 (1-1/2 in.) nominal

Discharge: DN 38 (1-1/2 in.) NPT(F)

RX33 Performance Data

- Max. flows: 55 L/min

- Max. differential pressure: 8.6 bar (125 psi)

For more detailed information download the RX10 data sheet or the RX33 data sheet.

Construction Features

- Low maintenance – two stage impeller design

- Low NPSH booster first stage impeller

- Direct coupling to standard 2-pole motors-EExe or EExd protection

- Simple balanced mechanical seal

- Throttle bush meets API 682 – ISO 21049 standard

- Extremely quiet, vibration free operation

- Very simple to service

Materials of Construction

- Casing – Ductile Iron/Steel

- Impellers – Stainless Steel/Bronze as standard

- Shaft – High tensile alloy steel

- Special materials to specification.

Range of performance

- Flows to 138 L/min

- Pressures to 2400kPa

- Power Range to 7.5kW

- Speeds to 3500 RPM

Model Lineup

- RB10 – 91 L/min @ 700kPa (7 Bar) – 50Hz

For more detailed information download the RB10 data sheet.

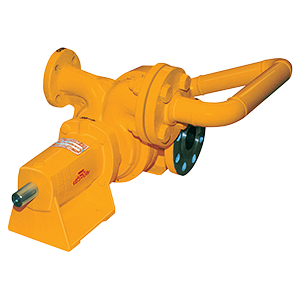

Ebsray is pleased to introduce the next evolution in LPG transport pumping with their R75 Series high volume LPG turbine pump. The Model R75 Series Regenerative Turbine Pumps, featuring Ebsray Turbine Technology™, are designed and precision-built from the ground up, specifically for the unloading of LPG tank trucks.

The R75 can run smoothly and quietly across its range even in poor suction conditions. Designed with no contact between the impeller and pump body, the R75 pump offers less wear and vastly increased times between maintenance.

Features & Benefits:

The Next Evolution in LPG Transport Pumping

- Dimensional fit for existing Ebsray and competitive pumps installations

- Simple, single-stage design with fewer rotating parts and smaller footprint than a side-channel pump

- Ductile iron pressure retaining parts

- No contact between the impeller and pump body

- Designed for hydraulic and PTO drive

- Can operate at 3,500 rpm allowing close coupling to 2 pole motors on bobtails and in fixed installations

Technical Data

- Flow rates to 480 L/min

- 14 bar (203 psi) differential pressure for higher flow through all delivery hoses for shorter fill times

- Complies with ATEX and AS1596 Codes (UL51 certification currently in progress)

For more detailed information download the RB75 data sheet.

The Ebsray Bypass/Pressure Relief Valves are specifically designed for a wide variety of industrial services. The easily adjustable differential-pressure settings provide accurate and repeatable performance that enables full pump flow while maintaining controlled preset maximum pressure.

Applications

- Autogas driveway dispensing

- Forklift refueling

- Aerosol industries

- Agricultural industries

- Marine dispensing

- Cylinder filling

- Direct burner or vaporizer feed

Features & Benefits

- 90º porting arrangement

- Flanged ANSI Class 300 or threaded (NPT) ports available for most models

- Adjustable pressure setting within spring range for optimum dispensing flow rates

- Low pressure rise

Optional valve types-application dependent:

- CBS – Constant Bleed System

- VRS – Vapour Removal System

- NRV – Non-Return Valve (refer Ebsray for details)

Technical Data

Materials:

- Pressure Casings: Ductile iron to ASTM A395

- Elastomers – Viton® – as standard

- Special materials to specification

Porting:

RV18: DN 25/1 in. flanged ANSI 300 screwed NPT(F)

RV19: DN 38/1-1/2 in. flanged ANSI 300 screwed NPT(F)

Performance Data

- Max. flows:

RV18: 200 L/min

RV19: 600 L/min

- Diff. pressures to 14 bar (200 psi)

- Hydrostatic test pressure: 70 bar (1,016 psi)

Further information can be found by contacting us or visiting the Ebsray website.